GST™

Introduction to GST™

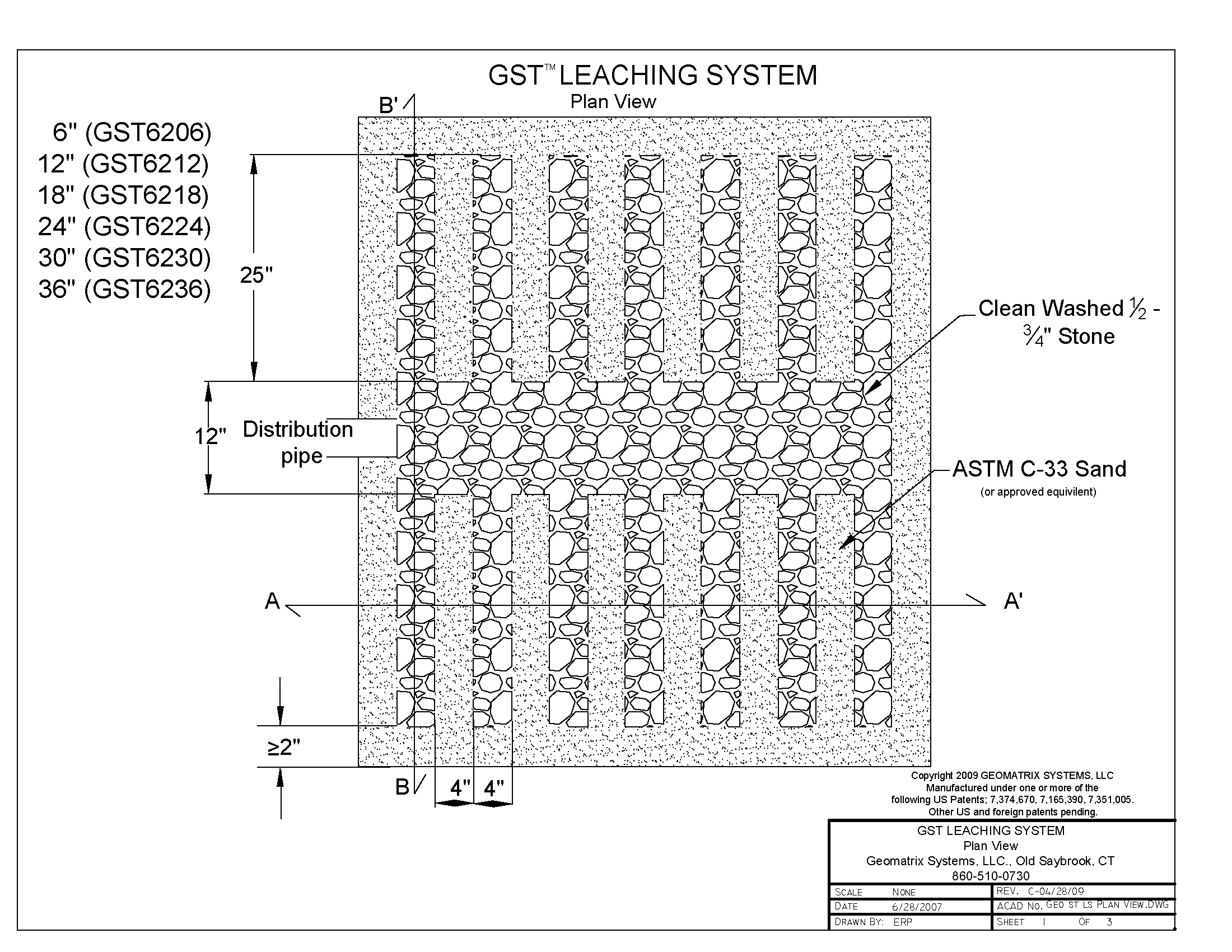

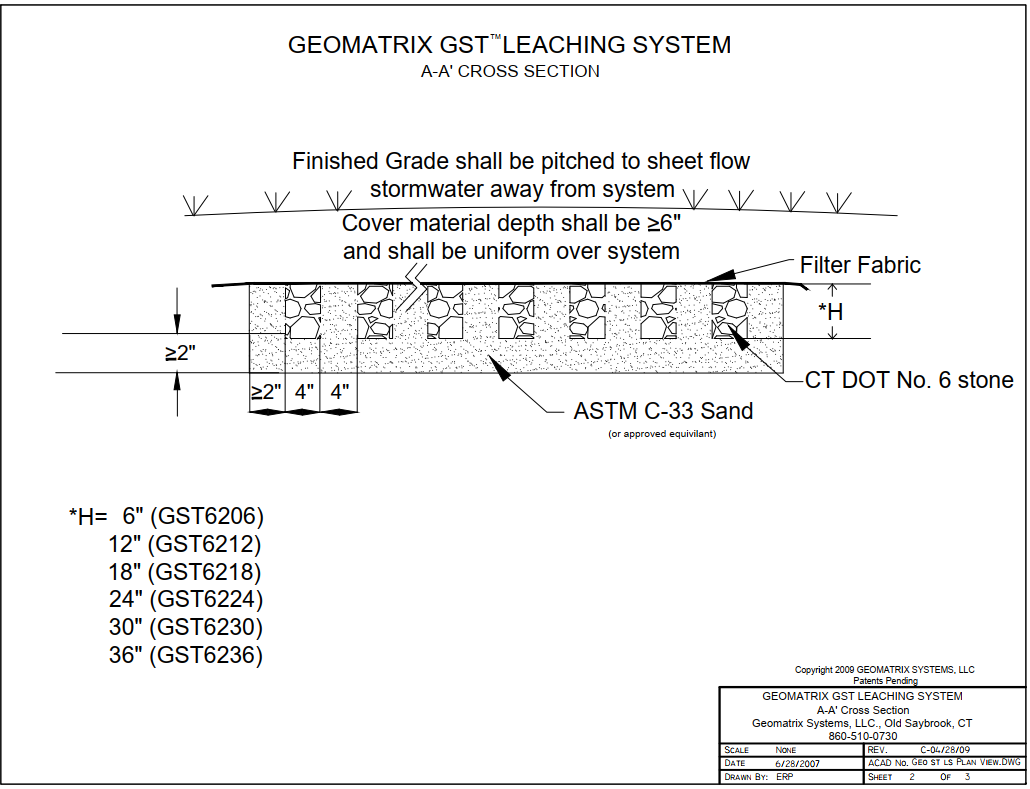

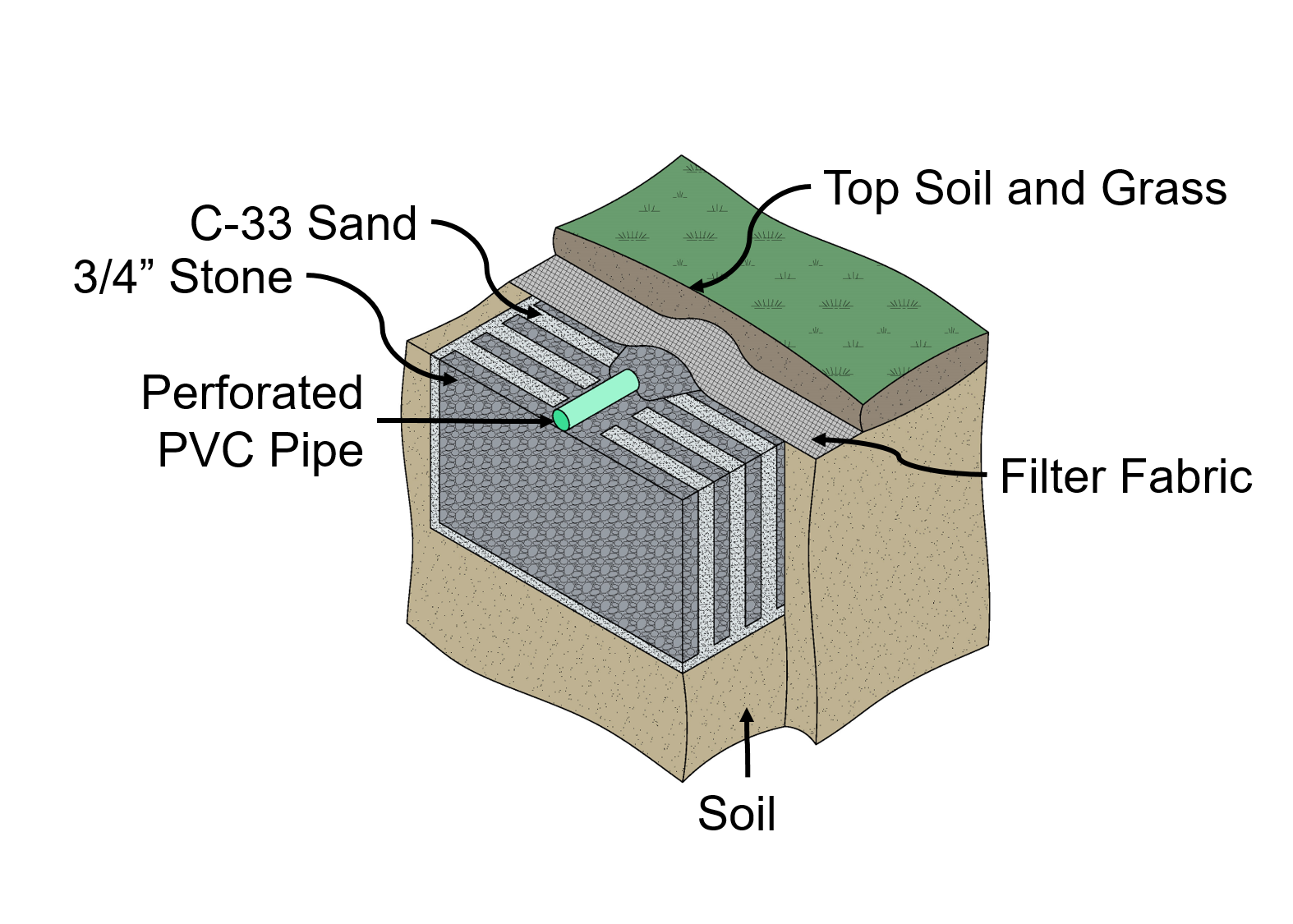

The GST™Leaching System (GST), is an adaptation of the time proven stone leaching trench. This traditional leaching system has been improved with the use of a removable form to accurately shape and construct leaching fingers along the sides of a central distribution channel. The fingers are constructed with ½” – ¾” washed stone and are surrounded with ASTM C-33 sand. These fingers serve to increase the sidewall surface area by more than six times that of a traditional stone leaching trench. The increased sidewall area mitigates any negative hydraulic effect fines, introduced in dirty stone, may have on the bottom area of the system. Additionally, the narrow profile of the leaching fingers and central distribution channel, combined with the uniform profile of the sand treatment media, serve to enhance oxygen transfer efficiencies. Enhanced oxygen transfer results in better treatment of the wastewater pollutants and a leachfield with a longer lifespan.

Combining our GST and SoilAir systems can reduce organic matter in high strength wastewater.

GST can be configured with standard gravity, pressure and/or time dosed distribution. The GST is available 6”, 12”, 18”, 24”, 30”, and 36” tall, 37” or 62” wide.

GST 37 & 62 Sizing and Sand and Stone Charts

GST Installation Instructions

GST inspection port

Every GST system is required to have an inspection port on every row and a Geomatrix GST System Identification label engraved on one of the inspection port caps (SID cap). The inspection port (PN: IPGST15) consists of a 4” PVC SDR 35 Tee with two slotted opening on the T ends. A threaded plug on top prevents debris from entering the inspection port. The SID cap included the GST model#, total length of the system and other pertinent information about the system installation.

These inspection ports are designed to be stable and not move upwardly or downwardly over the life of the system. This will allow confirmation of the bottom elevation of the leaching system during inspection or at any time afterwards. It is also possible to monitor effluent ponding levels through this port. If it is ever necessary to pump the leaching system out, the inspection port will prevent a “posthole” from being formed as occurs when an open bottom pipe is utilized for pumping. The inspection ports can be finished in a valve box to be flush with grade.

The SID cap will be manufactured upon receipt of the signed proposal and mailed from Geomatrix Systems, LLC.